Master Expert Tips for Using Metal Roof J Channel Effectively and Efficiently

Master Expert Tips for Using Metal Roof J Channel Effectively and Efficiently

When working with metal roofing projects, understanding how to use metal roof J channel effectively and efficiently can save time, enhance durability, and improve the overall aesthetic of the installation. The J channel, a vital component in metal roof systems, acts as a finishing trim that channels water away from edges and openings, preventing leaks and offering a clean, professional look. Whether you’re a DIY homeowner or a professional roofer, mastering the use of the J channel can make a significant difference in your project’s success.

What Is Metal Roof J Channel and Why Is It Important?

Metal roof J channel is a type of trim shaped like the letter “J” and is commonly used around the edges of metal roofing sheets, doorways, windows, and other openings. It serves multiple purposes including:

– Protecting edges from weather exposure and water infiltration

– Providing a seamless transition between metal panels and other building elements

– Enhancing the finished appearance of the roof

Because it directs water away and shields vulnerable areas, installing J channel correctly is crucial to preventing costly water damage and structural issues.

Planning and Preparation for J Channel Installation

Before you begin, careful planning is essential to ensure efficient use of metal roof J channel. Consider the following expert tips:

Measure Accurately

Incorrect measurements are a common mistake that leads to wasted material and poor fit. Measure all edges meticulously and account for overlaps and fastener placement. Remember to check corners and around openings where the J channel might need cutting or adjustment.

Choose the Right Material and Finish

Metal roof J channels come in various materials such as aluminum, galvanized steel, and sometimes copper. Choose a material that matches or complements your metal roof panels for a cohesive look. Additionally, consider the finish: painted or coated materials offer extra protection against corrosion and weathering.

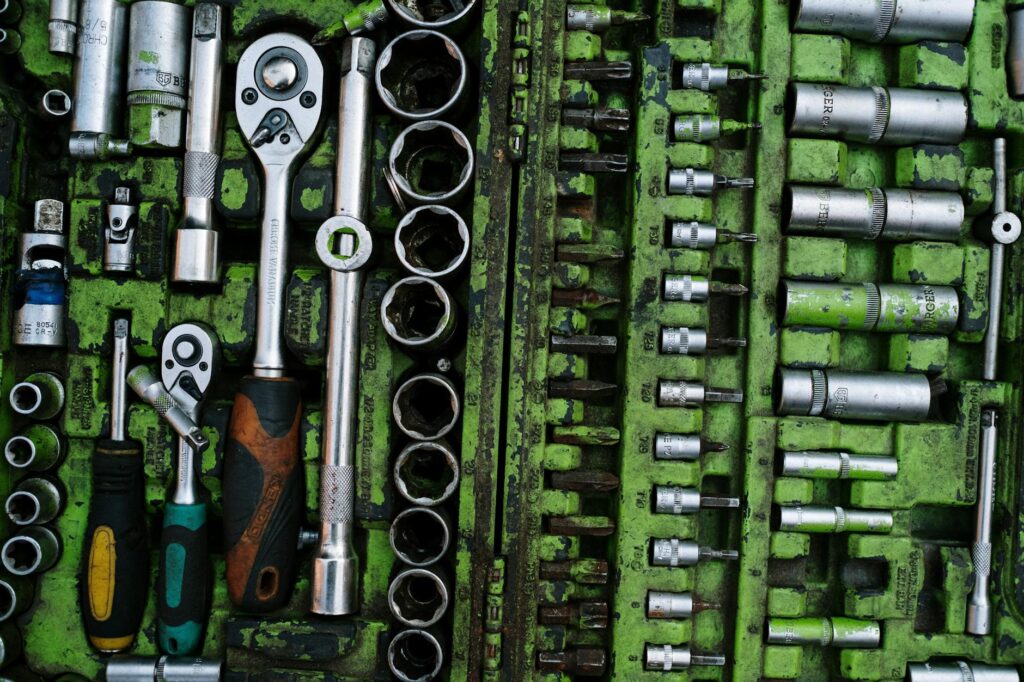

Gather Proper Tools and Safety Equipment

Preparing the right tools—tin snips, metal cutting saws, drill, and fasteners—will streamline the process. Personal protective equipment like gloves and safety goggles are also essential when handling sharp metal edges.

Step-by-Step Guide to Using Metal Roof J Channel Effectively

1. Installing Under the Metal Roof Panels

The J channel is typically installed beneath the metal panels but over the building’s weather barrier or underlayment. This layering helps channel water away effectively. Secure the J channel firmly to the framing, ensuring it sits flush to avoid gaps.

2. Making Precise Cuts for Corners and Openings

Corners and openings require special attention. Use a miter saw or metal snips to create accurate 45-degree cuts for inside and outside corners. Overlapping joints by a couple of inches and using sealant where joints meet can help improve waterproofing.

3. Securing the J Channel With the Right Fasteners

Use self-drilling screws with rubber washers to secure your J channel in place. These fasteners prevent leaks by sealing the holes they create. Space screws evenly—usually every 8 to 12 inches—and avoid over-tightening, which can deform the metal.

4. Sealing for Maximum Protection

Apply a high-quality exterior-grade sealant to all joints, cuts, and around fasteners for extra protection against moisture. Be careful not to over-apply, as excess sealant can detract from the appearance and may cause dirt accumulation.

Common Mistakes to Avoid When Using Metal Roof J Channel

Mastering the use of the J channel also means learning from common pitfalls:

– Ignoring Overlaps: Proper overlapping ensures water sheds correctly. Without it, you risk leaks and water damage.

– Poorly Aligned J Channels: Misalignment leads to gaps and a sloppy finish. Take time to align and double-check before fastening.

– Not Accounting for Thermal Expansion: Metal expands and contracts with temperature changes. Leave slight gaps and use flexible sealants to accommodate this movement.

– Neglecting Underlayment: Installing J channel without appropriate underlayment can undermine waterproofing.

Enhancing Efficiency: Tips for Speeding Up J Channel Installation

Efficiency doesn’t mean rushing; it means smart preparation and execution. Here’s how to work faster without sacrificing quality:

– Cut Pieces in Advance: Prefabricate J channel segments according to your measurements in a dedicated workspace.

– Use a Template: Create a cardboard template for corner cuts and openings to ensure repeatable accuracy.

– Work in Sections: Install J channels in manageable sections to maintain focus on precision.

– Organize Fasteners and Tools: Keep all your screws, sealant, and tools close at hand to avoid unnecessary movement.

Conclusion

Using metal roof J channel effectively and efficiently is an art that combines precise measurement, correct installation techniques, and attention to detail. By following these expert tips, you not only improve the durability and performance of your metal roofing system but also achieve a polished, professional finish. With the correct approach, metal roof J channels become more than just trim—they become a key element in your roofing success.